Get a Quote

Environmental Impacts of Lithium Ion Batteries in Electric Vehicles

As more individuals opt for electric vehicles, grasping the influence of lithium-ion batteries on the environment gains significance. These batteries power numerous EVs, yet their manufacturing and disposal can influence air, water, and land. This article will examine the advantages and disadvantages of lithium-ion batteries in electric cars, aiding you in understanding their lifecycle and implications for our planet.

Overview of Lithium Ion Batteries in Electric Vehicles

Lithium-ion batteries are the powerhouse behind the current revolution in electric vehicles (EVs). These batteries are favored for their high energy density and efficiency, allowing EVs to travel longer distances between charges. They feature cathodes made from materials like lithium iron phosphate and anodes that enhance energy storage efficiency. This efficiency boosts the performance of electric cars, making them a favored option for renewable energy transport. As we steer away from fossil fuels, the role of lithium-ion batteries in transportation is increasingly pivotal.

Current Trends in EV Adoption Globally

The global adoption of electric vehicles (EVs) has surged dramatically over the past decade, according to the International Energy Agency's Global EV Outlook 2024. It is driven by a growing awareness of environmental issues and supported by governmental policies promoting sustainable energy. Countries like Norway, China, and the United States are leading the charge, offering incentives for EV purchases and investing in charging infrastructure to facilitate this shift.

Lithium-ion batteries are increasingly used in electric cars due to advancements in charging infrastructure. Governments offer incentives to encourage EV adoption and aim to decrease greenhouse gas emissions associated with climate change.

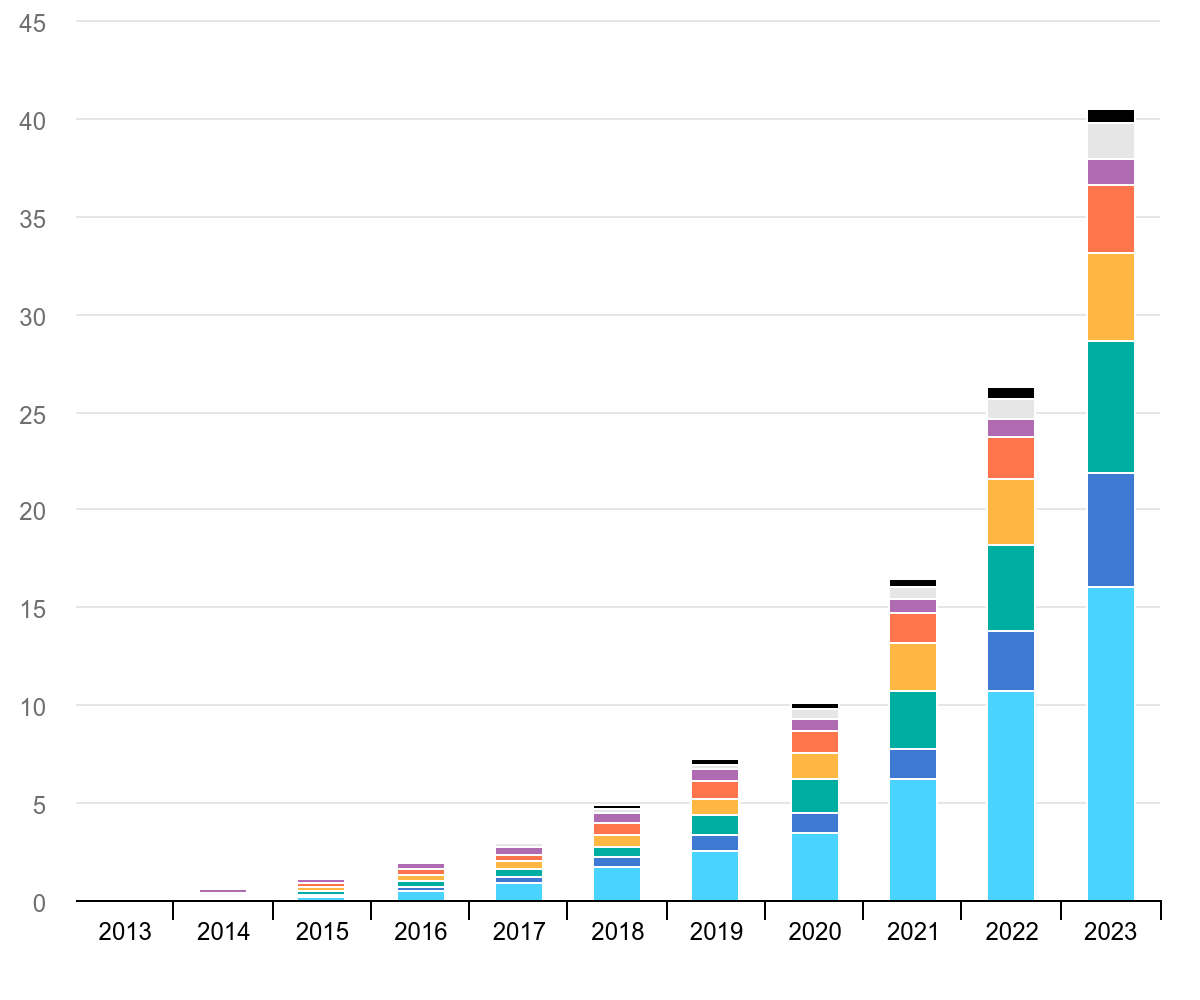

Data from the IEA report illustrates a steep upward trend in global electric car stock from 2013 to 2023. Starting from a modest base in 2013, the total number of electric cars worldwide has surged, particularly from 2020 onwards, reflecting increased consumer acceptance and substantial policy support from governments worldwide. By 2023, the number of electric vehicles in operation globally reached unprecedented levels, underlining the shifting dynamics of the automotive industry towards electrification.

Environmental Impacts of Lithium Ion Batteries in Electric Vehicles

While EVs significantly reduce emissions during operation, their environmental impact is not negligible, especially concerning the batteries they rely on. The production, usage, and disposal of lithium-ion batteries have various environmental repercussions.

EV Lithium ion Battery Mining Environmental Impact

The extraction of lithium, cobalt, and nickel—key components of lithium-ion batteries—often involves intensive mining operations. These processes can lead to significant environmental degradation, including habitat destruction and water pollution. Mining processes for lithium-ion batteries involve several steps such as brine extraction, hard-rock mining, and processing of lithium-rich clays.

In Chile, lithium is extracted from salt brines, while countries like Australia focus on hard-rock deposits, like spodumene ores. However, extraction techniques like open-pit mining and brine extraction can lead to pollution, soil degradation, and biodiversity loss, impacting local communities. In contrast, brine extraction tends to use less land but can cause water shortages and contamination of freshwater sources.

As the appetite for electric cars rises, addressing health risks and fostering environmentally responsible practices in lithium mining is vital for a sustainable future.

EV Lithium ion Battery Production Environmental Impact

The environmental impact of lithium-ion battery production is significant, particularly due to the intensive processes involved in extracting and processing the raw materials required for these batteries.

Water Usage and Environmental Strain

The production of lithium-ion batteries is a water-intensive practice, especially concerning the extraction of lithium. Regions like the Lithium Triangle in South America, which includes Chile, Argentina, and Bolivia, face severe water depletion challenges. For instance, in Chile's Salar de Atacama, lithium extraction consumes about 65% of the region's water resources. This heavy water use in arid regions not only stresses local water supplies but also impacts local ecosystems and communities.

Carbon Footprint

The carbon emissions from manufacturing lithium-ion batteries are substantial. A study found that 46% of an electric vehicle's (EV) emissions come from the production phase, compared to only 26% for internal combustion engine vehicles. It is estimated that nearly 4 tonnes of CO2 are emitted during the production of a single electric car. Therefore, an EV needs to be operated for several years to offset these initial higher emissions through reduced operational emissions compared to conventional vehicles.

The environmental impact extends beyond the extraction of raw materials. The chemical processes involved in manufacturing batteries can also lead to pollution if not properly managed.

Recycling Lithium Batteries and Its Environmental Benefits

Recycling lithium-ion batteries presents its own set of challenges, primarily due to the complex technology and the high costs associated with the recycling process. The most common methods for recycling lithium-ion batteries from electric vehicles include mechanical recycling and pyrometallurgical recovery. Mechanical recycling involves physical processes to separate materials like cathodes and anodes, while pyrometallurgical recovery entails smelting to extract lithium and other metals.

These processes influence the recovery percentage of materials such as lithium, cobalt, and nickel, which are significant for battery technology, but efficiency remains a challenge. Contamination during recycling can lead to pollution and health risks for local communities, particularly those near lithium mining operations.

Currently, only a small percentage of lithium batteries are recycled globally, which contributes to environmental degradation when these batteries end up in landfills. Advanced recycling technologies are essential for improving recycling rates and reducing the overall environmental impact of these batteries.

Read more: Are Lithium Batteries Sustainable?

EV Lithium Battery Replacement

Electric vehicle (EV) lithium battery replacements are focusing on more sustainable and efficient alternatives, including:

Solid-State Batteries: These batteries replace the liquid electrolyte in traditional lithium-ion batteries with a solid electrolyte. They are safer, have higher energy densities, and can charge faster.

Sodium-Ion Batteries: Sodium-ion batteries offer a potential cost-effective alternative to lithium-ion batteries, using abundant and cheap sodium. They are considered for both grid storage and transport applications.

Lithium-Sulfur Batteries: Offering higher energy density and potentially lower environmental impact, lithium-sulfur batteries are another area of research but face challenges in lifespan and stability.

Graphene Batteries: Incorporating graphene can enhance the performance of lithium-ion batteries or lead to new types of batteries with faster charging times and increased capacity.

These advancements aim to address the environmental and practical limitations of current lithium-ion batteries by improving efficiency, safety, and sustainability.

Final thoughts

As we navigate the complexities of environmental impacts associated with lithium-ion batteries in electric vehicles, it's clear that despite the challenges, these batteries remain the best option currently available for powering EVs.

Our commitment at EverExceed to advancing battery technology is steadfast, with a continuous focus on improving the environmental footprint of these essential components. Our EV lithium batteries are designed not only to enhance vehicle performance but also to align with global sustainability efforts, making them a responsible choice for today's eco-conscious consumers. As technology evolves, so does our promise to deliver solutions that meet both the needs of our customers and the demands of the environment.

FAQ

Are lithium-ion batteries bad for the environment?

Lithium-ion batteries, commonly used in electric vehicles, have both positive and negative environmental impacts. On the positive side, they help reduce greenhouse gas emissions by powering electric vehicles, which are cleaner alternatives to gasoline-powered cars. However, the mining and processing of lithium and other metals required for these batteries can cause environmental degradation, including water depletion and pollution. Moreover, improper disposal of these batteries can lead to soil and water contamination. Efforts are ongoing to improve battery recycling rates and reduce their environmental footprint.

How does battery production affect greenhouse gas emissions?

Battery production contributes to greenhouse gas emissions primarily through mining, manufacturing, and transportation processes. To mitigate this, choose batteries made with recycled materials, support manufacturers with sustainable practices, and consider using renewable energy sources during production to reduce overall emissions.

What happens to lithium ion batteries at the end of their life cycle?

At the end of their life cycle, lithium-ion batteries should be recycled at designated collection points. Many retailers and municipalities offer drop-off options. Recycled materials can be reused in new batteries or other products, reducing waste and environmental impact.

Are there sustainable alternatives to lithium ion batteries for electric vehicles?

Yes, alternatives to lithium-ion batteries include solid-state batteries, which use solid electrolytes, and sodium-ion batteries, utilizing abundant sodium resources.

How can recycling programs mitigate the environmental impacts of lithium ion batteries?

Recycling programs can reduce environmental impacts by recovering valuable materials like lithium and cobalt, minimizing mining waste.